Overmolding Services

- Home »

- Services »

- Overmolding »

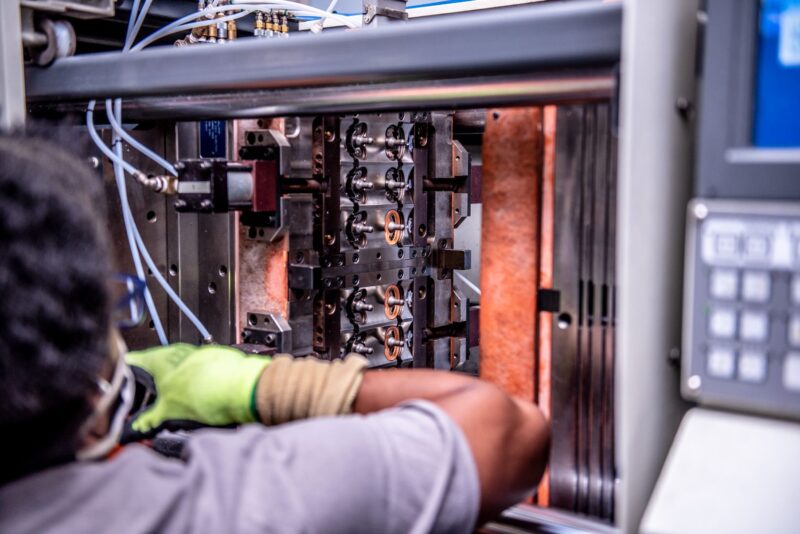

Our overmolding services bond different materials into a single, functional part, perfect for creating soft-touch grips, watertight seals, and durable components for a wide range of applications. As a US-based manufacturer, we specialize in complex projects requiring precision and expertise.

The Overmolding Process

Overmolding is a multi-step injection molding process where two or more materials are layered to create a single, integrated product. The process begins by molding a rigid base component—known as the substrate—from a material like plastic.

This substrate is then placed into a second mold, where a softer material, such as silicone or a thermoplastic elastomer (TPE), is molded over, onto, or around it. The result is a seamless chemical and mechanical bond between the materials, producing a finished part with enhanced functionality, durability, and aesthetics.

Plastic Overmolding

We specialize in plastic-on-plastic overmolding to create sophisticated parts with unique characteristics. This process allows for the combination of rigid and flexible plastics, adding soft-grip handles to tools, ergonomic features to consumer products, or colored accents for branding.

By selecting compatible thermoplastics, we ensure a robust molecular bond that results in a durable, single-piece construction ready for demanding applications.

Silicone Overmolding

Silicone overmolding offers unparalleled performance for products requiring flexibility, biocompatibility, and resistance to extreme temperatures. We commonly overmold liquid silicone rubber (LSR) onto plastic and metal substrates to create soft, non-slip surfaces for medical devices, waterproof seals for electronics, and safe, durable components for infant care products.

Our expertise in silicone ensures a superior bond and a high-quality finish for your most critical parts.

Specialized Overmolding for Electronics

Protecting sensitive electronic components from moisture, dust, and impact is critical for product reliability. Our silicone overmolding services provide a robust solution for encapsulating circuit boards, cables, and sensors. This process creates a watertight, vibration-resistant seal that significantly enhances the durability and lifespan of electronic devices. Whether for consumer gadgets or industrial equipment, we can design an overmolding solution that meets your exact specifications for protection and performance.

By selecting compatible thermoplastics, we ensure a robust molecular bond that results in a durable, single-piece construction ready for demanding applications.

Start Your Overmolding Project

Ready to enhance your product with the benefits of overmolding? Our team is here to help you navigate material selection, design for manufacturability, and production. As a dedicated, US-based manufacturing partner, we are committed to delivering high-quality components on time and on budget.

Explore Our Overmolding Resources

Two-Shot Molding vs. Overmolding: What’s the Difference?

If you're manufacturing a product that requires multiple materials or enhanced durability, two advanced molding techniques often come into play: ...

Read More →Silicone Overmolding Secrets

Silicone overmolding is an injection molding process that molds silicone over, under, or through a substrate material to complete the final part. By ...

Read More →How to Reduce the Cost of Your Injection Molding Project

Injection molding projects can be a very cost-effective way of creating high-quality products at high volumes but we know that, as a business, it’s ...

Read More →