Our Services

- Home »

- Our Services »

Injection Molding

Inventors and engineers rely on Extreme Molding for silicone injection molding applications that require innovation and attention to detail.

We specialize in:

- High end consumer and life science applications that are technically challenging

- Applications that require high-performance materials, including food-grade and Class 6-compliant silicones

- Multi-material part constructions, including embedded electronics and overmolding of silicone over plastic or metal substrates

Start by sending us your prototype or CAD files, and we will work with you to fully understand your design and performance requirements. We will ensure that you receive the injection molding services that your product requires.

Overmolding

Extreme Molding is one of the few custom molders in the United States to offer silicone overmolding to plastic and silicone molding at the same location.

- Molding combinations of silicones, plastics, metals, and electronics

- Application of medical adhesives to molded parts

- Assembly of your product in a Class 100,000 white-wall environment

Using our knowledge of regulatory requirements for medical and food-use applications, we’ll help you select the right overmolding material combination.

Compression/ Transfer Molding

Extreme Molding now offers silicone HCR transfer molding

- Apples to apples transition from overseas to domestic supply

- Low cost silicone materials

- Customizable silicone materials

- Accommodates large> 1lbs silicone part manufacture

- Very high cavitation molds achievable

Packaging and Fulfillment

We can help take the burden out of selling your product.

How we can help with packaging and fulfillment:

- Place items in retail packaging

- Just-in-time (JIT) produce in our upstate New York facility

- Process orders via your website, Amazon, or other retailer

- Ship directly to consumers, retail stores, and distributors anywhere in the world

Are you dissatisfied with the molding service you are receiving from another vendor, in the United States, or overseas? Now is the time to talk to Extreme Molding.

Color Matching

At Extreme Molding we can easily request a pigment sample of any pantone color and use it in any silicone for most hardnesses — from 10 durometer to 80 durometer (these are units of measure of hardness in silicone).

Our Color Matching Products:

- Pantone Match

- Physical Match

- Choosing a Color for FDA Compliance

At Extreme Molding we have a large team of experts who can help you select the materials and color of your product, creating the perfect combination of both.

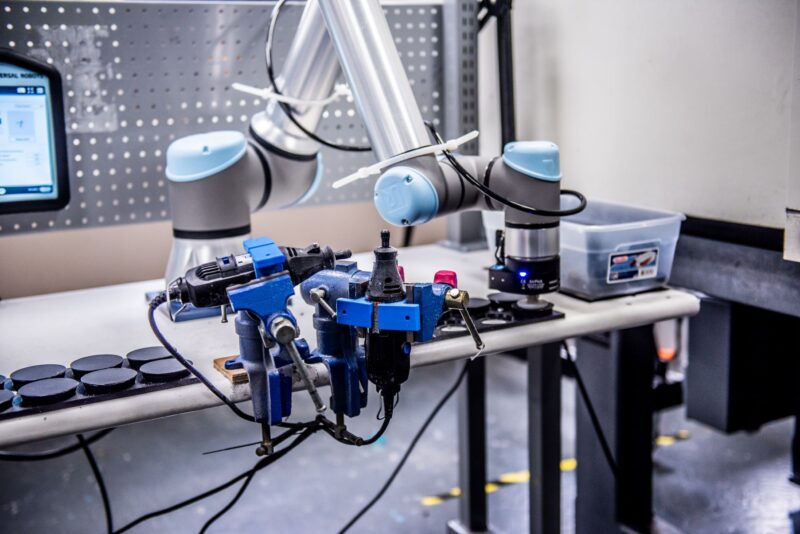

Value Added Secondary Operations

We can simplify and automate post-molding tasks with our cost-efficent secondary services. This includes:

- Adhesives

- Post-Curing

- Die Cutting/Hole Punching/Slitting

- Additional Services

Launch a Product

If you have a great idea, we can help bring it to life. We’ve done this before and enjoy becoming partners throughout product creation. From advising you through the mold sourcing process, to delivering your new product to customers, we want to work with you every step of the way.