In the silicone injection molding industry, there are two common injection mold tooling approaches. The two approaches are conventional and cold deck. At Extreme Molding, we have migrated towards cold deck tooling for our silicone products to reduce waste, increase throughput, and decrease cycle times. Before we can dive into the pros and cons of each method, we need to understand the sprue and runner system. The sprue and runner system of an injection mold design is the path machined through the mold plates to connect the nozzle to the injection mold cavities. It is the primary pathway used to get the material to flow from the nozzle to the cavities within the injection mold. In silicone mold design, there are two primary ways to design the sprue and runner system: Conventional vs Cold Deck.

Conventional Method

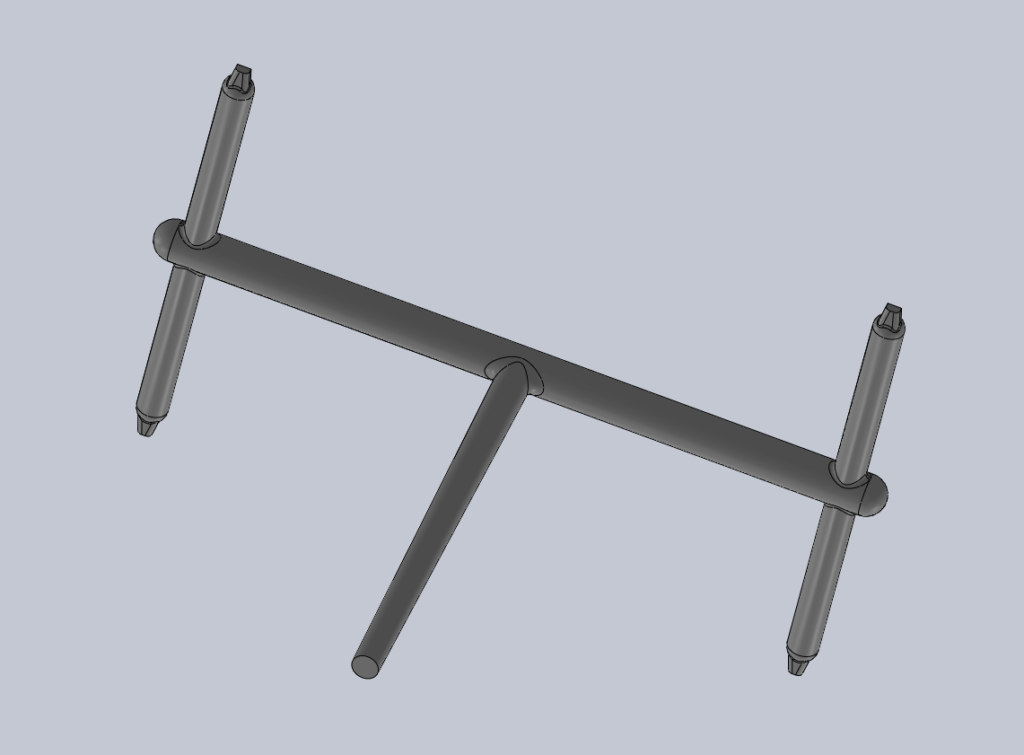

The conventional method consists of interconnected channels that each lead to an individual cavity. Below is an example image of a conventional sprue and runner system. As displayed in the picture, the process starts from a central location (bottom middle) and branches out to 4 different individual cavities. While it is typically the least expensive and easiest to start up, the sprue and runner system is scrapped and can often lead to longer cycle times.

Along with the conventional method being more economical up front, you can also expect shorter lead times (12-14 weeks on average). However, there are a few cons to using this method as well. The conventional method is not sustainable as it produces more waste than is necessary. It also has a slower cycle time because of cure and sprue removal. Sprue removal also makes the process harder to automate.

Cold Deck Tooling

To combat the longer cycle times and waste, a cold runner can be implemented. The cold runner approach removes the sprue and runner system by directly injecting material into each cavity using smaller injection nozzles. The term “cold” refers to the fact that there is a chilled water solution surrounding each of the individual injection nozzles and allowing the material to stay uncured until it reaches the outer wall of the cavity.

The cons of using the cold deck tooling method are that the molds can become very expensive and there can be longer lead times (20-24 weeks on average). The method can also be harder to implement and transition to other facilities.

However, at Extreme Molding our team sees the pros outweigh the cons when using the cold deck tooling method. This includes faster cycle times, individual process control over each cavity, and that it can be more easily automated. Cold deck tools offer the possibility for higher cavitation due to the material that is saved by not having a sprue. The best benefit we have encountered by making this switch has been that year to date, we have saved around 20,000 pounds of silicone from going into landfills because of cold-deck tooling. As a company that is committed to our sustainability efforts, this switch was an easy decision.

For questions regarding conventional vs cold deck tooling methods for silicone products, please contact our team.